Reactive Printing

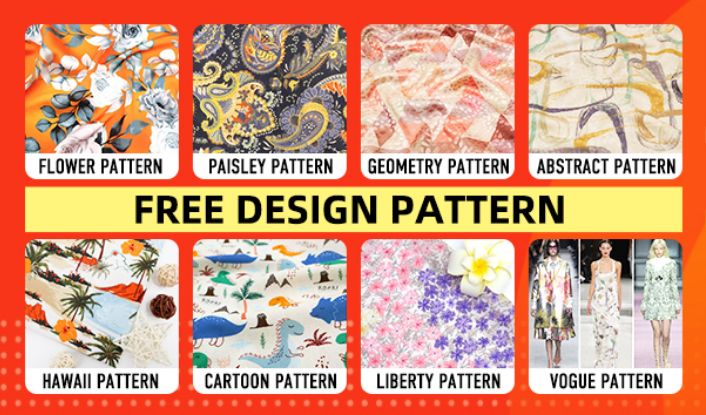

As the name implies, our printing dyes are processed by reactive printing and dyeing. The design elements of the reactive printing are quite diverse: plant flowers, geometric figures, English letters and different color blocks are organically combined to show different design styles through design techniques. Such fabrics are suitable for a wide range of groups and have a long application time. The fabric of reactive printing has bright color, good color fastness, soft feel, can be washed frequently without fading, and can be used as new for a long time.

Generally, reactive printing and dyeing can ensure that environmental protection is harmless to people, color and fabric feel better, and there will be no hard and soft feeling.

Pigment printing

It uses thermosetting or thermoplastic synthetic resin as the adhesive, and mixes with insoluble pigments to form pigment printing paste, which is coated on the surface of the fabric by mechanical or manual methods, and then forms a film after drying and baking, so that the pigment can be tightly covered on the fiber to achieve the purpose of printing and coloring. Pigment printing paste is generally composed of pigment paste, adhesive, photo-coupler and emulsion paste, which can be mixed when used.

Pigment printing is the cheapest printing method in printing production, because the printing of pigment is relatively simple, requires the least process, and usually does not need steam and water washing. The paint has bright and rich colors and can be used for all textile fibers. Their light fastness and dry cleaning fastness are good, even excellent, so they are widely used for decorative fabrics, curtain fabrics and clothing fabrics that need dry cleaning. In addition, the coating will hardly produce large color difference on different batches of fabrics, and the coverage of the base color is also very good when covering printing.

With continuous washing or dry cleaning, pigment printing will gradually fade and the color will become lighter. This is due to the continuous rotation and stirring during the cleaning process, which causes the resin adhesive to fall off gradually. Generally, after 20-30 times of cleaning, this kind of printed cloth will have obvious fading phenomenon. The color fastness of the fabric is improved due to the application of resin and silicon softener in the finishing process. It is worth noting that dark colors fade more easily than light or light colors.

The paint makes the hand feel hard at the printing part of the fabric, which is not obvious in light color, but very prominent in dark color. The paint is not particularly wear-resistant, especially dark color. Dark paint should be especially avoided in fabrics such as furniture decoration.

Difference between the two

1. Different processes

Pigment printing uses thermosetting or thermoplastic synthetic resin as the adhesive, mixed with insoluble pigments to form pigment printing paste, which is coated on the surface of the fabric by mechanical or manual methods, and then dried and baked to form a film, so that the pigment can be tightly covered on the fiber to achieve the purpose of printing and coloring.

Reactive printing: In the process of dyeing and printing, the reactive groups of reactive dyes combine with the fiber molecules, making the dyes and fibers form a whole.

2. Different characteristics

Reactive printing and dyeing means that azo and formaldehyde are not added in the process of printing and dyeing, and it does not contain substances harmful to human body, and it does not fade when washing. The color and fabric feel good, and it will not feel hard and soft.

Pigment printing: The printed fabric has bright and bright color and good light stability. It can give the fabric a plump, dry and soft feel, especially the excellent rubbing fastness. The dry and wet rubbing fastness can reach ≥ 4 (for reference only) when used correctly. The washing fastness is excellent, and the fabric has good air permeability.

How to choose

The production process of pigment printing and reactive printing is used to explain which kind of printing is better: most machines can directly spray paint ink on textile fabrics. The applicable machine direct spray belt guide machine has simple and clear production process. Generally, the production process of using active ink needs to go through printing -- direct injection -- washing water -- steaming -- washing water. Generally speaking, it needs to go through the pretreatment and pretreatment of the process, and the production process is complex. Generally, there are many pigment printing.

The color fastness of pigment printing and reactive printing can be used to determine which is better: the color fastness of reactive printing is generally 4-5 grades, and the need to make it fade generally depends on whether the washing water rubs the color, and whether the high-temperature blisters fade. The color fastness of the paint is generally Grade 3, and it will not fade when washed in the washing machine. In general, from the perspective of color fastness, the color fastness of reactive printing is relatively good.

Brightness indicates which is better between pigment printing and reactive printing: reactive ink can penetrate into the fiber, and the color is very bright. The paint ink generally seeps on the surface of the fiber, and the brightness is relatively weak compared with the activity.

From the perspective of environmental protection, explain which kind of printing is good: the pigment ink spray printing process is generally printed on the front of the cloth, which is easy to be decomposed by nature, and fully meets the environmental protection requirements. Reactive printing penetrates into the front and back of the fabric, is difficult to be decomposed by nature, and is not environmentally friendly. Now the international community advocates the theme of environmental protection, and strictly checks and prohibits pollutants, so the market does not allow the situation does not allow, we choose pigment printing more.

In terms of production cost: the activity production process is very responsible, and its production cost is high, requiring many machines, and the finished product is also very expensive. The relatively active process of pigment printing is very simple, and the cost is relatively low. So you know what kind of printing you choose.

Shaoxing Kahn Co., Ltd. has a professional design team, a variety of flower designs, and can also provide you with customized printing services. Contact us to obtain the 2023 brand new product catalog

Post time: Feb-16-2023